Stros NOV 412 Industrial Elevator Sale

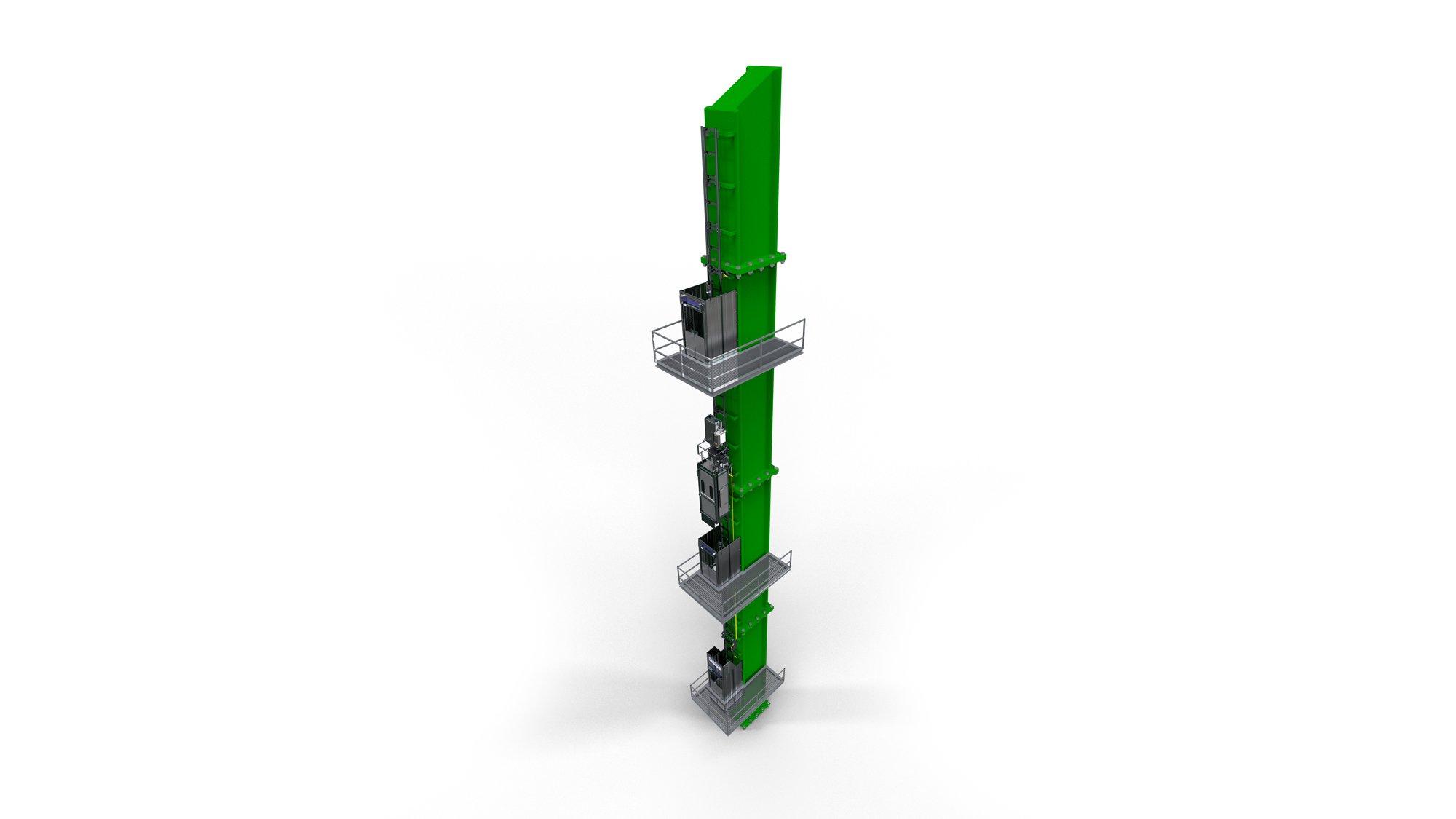

When looking for a small semi-permanent industrial elevator to access gantry cranes, ship-to-shore cranes or mineshafts the NOV 412 is an excellent choice. This rack and pinion machine is often purchased to offer safe maintenance access to large industrial structures. The industrial elevator system is designed by Stros to withstand harsh and abrasive environments during multiple years of operation. The payload capacity, automatic operation and robust built of this small elevator make for an excellent maintenance elevator for offshore industries, ports and bridges. Automatic self-lubrication is standard to all our industrial elevators for sale to prevent wear and damage from abrasive coastal weather or dust. Due to its shaftless elevator design, the NOV 412 is safe to operate during strong winds and harsh weather. In case of a power failure the elevator will lower itself automatically to prevent accidents or damage to the contents of the cabin.

General data

- Elevator configuration

- Payload capacity

- 2000 kg

- Maximum passengers

- people

- Lift speed

- 45 m/min

- Control

- Single automatic / Selective collective

- Frequency Control

- Optional

- Maximum travel height

- 350 m

- Maximum tie space

- m

Power supply

- Power supply

- Fuse

- A

- Rated power output (continuous duty)

- kW

- Power consumption

- kVA

Dimensions & weight

- Internal dimensions (WxLxH)

- 1280 x 910 x 2400 mm

- Base landing size (WxL)

- mm

- Required base landing height

- 1.25 mm

- Entry door (WxH)

- mm

- Opening width

- mm

- Weight base

- kg

- Mast section length

- m

- Weight mast section

- kg

Tailored configurations for the NOV 412 industrial elevator

Every industrial elevator from RECO Hoist Hire & Sales is customized to meet specific industry requirements. Whether you need adjusted cabin dimensions, higher load capacities, or reduced energy consumption, our elevators are designed to match your project’s needs. The NOV 412 model can be configured to operate with frequency control or direct-on-line (DOL) and can function in either fully or semi-automatic modes. For additional safety and convenience, options like overload protection and climate control (heating or air conditioning) for the cabin can be included.

Comprehensive service to ensure peak elevator performance

We provide a full range of maintenance services for industrial elevators, including inspections, on-site repairs, refurbishments, and engineering support. These services are tailored to the elevator’s specifications and its operational frequency to maintain optimal functionality. Regular inspections by our engineers help identify potential wear and erosion. If maintenance or repairs are needed, our technicians handle issues on-site, or a specialized team follows up quickly. Our collaboration with Stros and our experienced maintenance staff allow for swift replacement of any components. For further information about our maintenance services or to purchase a customized industrial elevator, contact our team or request a quote.